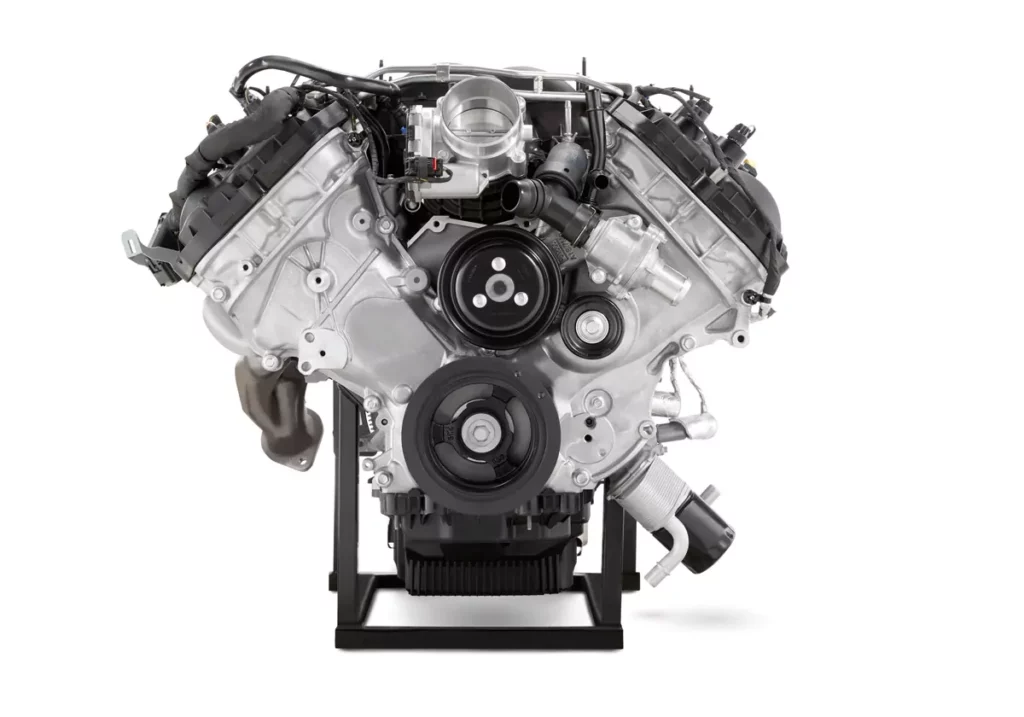

The Ford Coyote engine, a modern marvel of automotive engineering, offers a unique blend of power and efficiency. This guide dives deep into the process of integrating this engine into classic Ford Broncos and old Ford trucks, marrying historic design with contemporary performance.

Find What You’re Looking For

The Evolution of Power: Generational Overview of the Coyote Engine

The Ford Coyote engine, a masterpiece of modern automotive engineering, has undergone a remarkable evolution since its debut in 2011. Each generation of this iconic engine has brought significant advancements in power, efficiency, and technology, setting new standards in the automotive industry.

From the first roar of the Gen 1 Coyote in the 2011 Mustang GT to the sophisticated prowess of the latest models, this journey through the generations showcases Ford’s commitment to performance and innovation.

In this section, we’ll explore the key developments and enhancements in each generation of the Coyote engine, illustrating how it has become a symbol of modern muscle and a favorite for high-performance projects.

- Gen 1 (2011-2014): Introduced as a part of the 2011 Mustang GT, the first-generation Coyote engine was a significant step forward. It featured a 5.0L displacement and produced 412 HP and 390 ft.-lb. of torque. Key innovations included the use of dual overhead camshafts (DOHC) and an 11.0:1 compression ratio. This engine set the stage for the modern era of Ford performance engines.

- Gen 2 (2015-2017): The second generation brought improvements, most notably in power output. The horsepower was bumped up to 435, with torque increasing to 400 ft.-lb. This was achieved through refinements in the intake manifold, camshafts, and cylinder heads. The compression ratio remained the same, but the tweaks allowed for better breathing and efficiency.

- Gen 3 (2018-2023): This generation marked a significant overhaul. Horsepower jumped to 460, and torque increased to 420 ft.-lb. Major changes included the introduction of direct fuel injection alongside port injection, a higher 12.0:1 compression ratio, and a slight increase in bore size. These advancements led to a more robust power curve and improved efficiency.

- Gen 4 (2021-onward): The latest generation of the Coyote continues to push the boundaries. Though specific details vary by application, some models boast up to 486 HP. This increase is partly due to further refinements in fuel injection, variable valve timing, and ongoing improvements in engine calibration.

Spotlight on Gen 3 – The Heart of Modern Muscle:

Here are some technical advancements that make the Gen 3 Coyote engine an ideal choice for retrofitting projects:

- Increased Bore Size and Compression Ratio: The increase in bore size (from 92.2 mm to 93 mm) and the higher compression ratio (12.0:1) contribute to greater power output and efficiency. The larger bore allows for more air-fuel mixture to be burned, while the higher compression ratio ensures a more complete combustion process.

- Dual Fuel Injection System: The introduction of both direct and port fuel injection was a game-changer. This dual system allows for precise fuel delivery, improving both performance and emissions. Direct injection helps with efficiency and power at high engine speeds, while port injection is beneficial at lower speeds and helps to reduce carbon buildup.

- Performance Benefits: These technological improvements result in a more responsive and powerful engine, with a peak output of 460 HP and 420 ft.-lb. of torque. The Gen 3 engine provides a broad power band, making it suitable for a range of driving conditions, from daily commuting to high-performance applications.

Classic Integration: Coyote Engine in Ford Broncos and Trucks

Integrating the formidable Coyote engine into classic Ford Broncos and trucks is not just an upgrade; it’s a transformative journey that melds the soul of a classic with the heart of modern performance.

This process involves meticulous planning, precise engineering, the right parts, and a deep understanding of both the Coyote engine and the classic vehicle receiving it. From the first steps of selecting the right engine to the final touches of integration, this undertaking promises to rejuvenate vintage Ford vehicles with a surge of new power and efficiency.

In the following sections, we will delve into the specific steps and considerations necessary to successfully retrofit the Coyote engine into these timeless automotive icons.

Retrofitting the Coyote into Classic Ford Broncos:

- Engine Selection: Start by choosing the right Coyote crate engine. Ensure that it comes with the necessary wiring harness and control systems. Consider the engine’s power output and any additional modifications you might want (e.g., supercharging). This thing packs a punch!

- Preparing the Bronco: Inspect and prepare the Bronco’s engine bay. This includes removing the existing engine, cleaning the bay, and evaluating the condition of existing components (like mounts and crossmembers).

- Chassis Modification: The Bronco’s chassis may need to be modified to fit the larger Coyote engine. This could involve cutting and welding to enlarge the engine bay and reinforce areas to handle the increased power and torque.

- Transmission and Driveline Upgrades: The Coyote’s power output may exceed the limits of the Bronco’s original transmission and driveline. Consider upgrading to a stronger automatic transmission that can handle the increased power. Driveshaft and differential upgrades might also be necessary.

- Mounting the Engine: Custom engine mounts will likely be needed. A Coyote engine mount should be designed to position the engine optimally within the bay while ensuring proper alignment with the transmission. We have the Coyote parts and accessories you’ll need to make everything work.

- Cooling System: Upgrade the cooling system to manage the heat generated by the Coyote engine. This often involves a larger radiator and improved cooling fans. Again, these are parts you can get from us – like our two-row aluminum radiator kit. These high-quality aluminum tanks are TIG welded to the core and individually tested, guaranteeing a 100% leak-free performance.

Exhaust System: Fit a custom exhaust system. The Coyote’s exhaust ports and layout are different from the Bronco’s original engine, so new headers and exhaust pipes will be required. - Electrical and Electronics Integration: Integrating the Coyote’s modern electronics with the older Bronco’s systems can be challenging. Use the Coyote’s control pack and carefully plan the integration of the engine control unit (ECU), sensors, and gauges.

Adapting Old Ford Trucks for the Coyote Crate Engine Power:

- Engine Placement: Determine the optimal placement for the Coyote engine in the truck’s engine bay. This might involve modifying the firewall or fabricating new engine mounts.

- Drivetrain Modifications: As with the Bronco, upgrading the transmission, driveshaft, and differential may be necessary to handle the Coyote’s power.

- Custom Mounting Solutions: Develop custom mounts to secure the Coyote engine. Ensure these mounts provide stability and align the engine correctly with the transmission.

- Cooling System Upgrades: Upgrade the truck’s cooling system. This might involve a larger radiator and more efficient cooling fans to handle the increased heat output from the Coyote engine.

- Exhaust System Modifications: Fabricate a new exhaust system that fits the Coyote engine and accommodates the truck’s undercarriage and chassis design.

- Fuel System Adaptation: The engine may require a higher-pressure fuel system than the truck’s original setup. Installing a new fuel pump and modifying fuel lines will be essential.

- Electrical System Integration: Integrate the Coyote’s modern electronics, including the engine control unit, into the older electrical system of the truck. This process requires careful planning to ensure compatibility and functionality.

- You can opt for a Kincer Chassis with the crate engine already installed and save yourself a ton of time and you’ll know everything has been done right. Get your chassis at an amazing price and they’ll work with you to make sure you have all the information you’ll need to make an informed decision and can even ship the finished chassis to the builder of your preference or straight to you!

Technological Prowess of the Coyote Engine: Cutting-Edge Features for Optimal Performance

This section delves deeply into the technological advancements that make a Coyote crate engine a standout performer.

- Direct and Port Fuel Injection System: These engines utilize a combination of direct and port fuel injection. This dual system provides several benefits: direct injection improves combustion efficiency and power output, while port injection helps reduce carbon buildup on the intake valves. This combination leads to a more complete and efficient burning of fuel, contributing to the engine’s high power output and better fuel economy.

- Twin Independent Variable Camshaft Timing (Ti-VCT): Ti-VCT allows for precise control of the engine’s camshafts, optimizing the timing of valve opening and closing events. This flexibility improves the engine’s response across the entire RPM range.

At low RPMs, it enhances torque for better off-the-line acceleration, while at high RPMs, it boosts horsepower for peak performance. The system also contributes to improved fuel efficiency and reduced emissions by ensuring optimal combustion at all engine speeds. - Plasma-Transferred Wire Arc Cylinder Block: The Coyote engine features a plasma-transferred wire arc cylinder block, a significant advancement in engine block design. This technology involves spraying a thin layer of molten metal onto the cylinder walls, creating a coating that is harder and more durable than traditional cast iron sleeves.

This coating reduces friction between the piston rings and cylinder walls, improving efficiency and heat management. It also allows for a thinner and lighter block without sacrificing strength, contributing to the engine’s overall power-to-weight ratio.

Conclusion

The integration of the Ford Coyote Crate Engine into vintage Ford Broncos and old trucks is a journey that combines the nostalgia of classic designs with the thrill of modern performance. This guide aims to provide a comprehensive understanding and practical insights into this process, empowering you to bring new life to your classic vehicles.